PRODUCT OVERVIEW

Expanded Polystyrene (EPS) Geofoam is a geotechnical material, being used in construction activities in US, Japan and European Countries since 1970s. Its application in the construction and infrastructure industry is picking up in India.

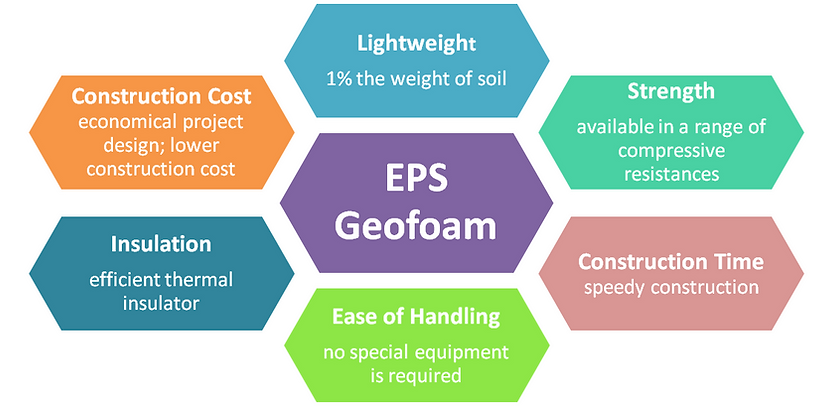

EPS Geofoam is approximately 1% the weight of soil and less than 10% the weight of other lightweight fill alternatives, making it a superior, ultra-lightweight fill material that significantly reduces the stress on underlying and abutting subgrades.

The use of EPS Geofoam typically translates into benefits like lower construction costs and faster construction schedules because it is easy to handle during construction, often without the need for special equipment. In addition, EPS Geofoam can be easily cut and shaped on a project site, which further reduces onsite challenges.

Its service life is comparable to other construction materials and it will retain its physical properties under engineered conditions of use. EPS Geofoam is produced in blocks that can be cut into various shapes and sizes. As an engineered product, it can be produced to obtain the required compressive resistance.

TECHNICAL SPECIFICATIONS

Physical Properties of EPS Geofoam as per ASTM D6817

Note: The kg/sq.mt. figures have been converted based on kPa figures specified by ASTM D6817. Conversion Factor: 1 kPa = 101.97 kg/sq.mt.

APPLICATIONS

CONSTRUCTION

INFRASTRUCTURE

ILLUSTRATIONS

Schematic illustrations of applications of EPS Geofoam:

Images Courtesy: www.geofoam.org

Live illustrations of applications of EPS Geofoam:

Image Courtesy: www.constructionspecifier.com

Image Courtesy: www.universalconstructionfoam.com

Image Courtesy: arcchicago.blogspot.in

CONSIDERATIONS

• EPS Density

• Compressive Strength

• Flame Resistance

• Moisture Absorption

• Chemical Resistance

• Design Methodology

• Allowable Stress

• Concentrated Loads

• Drainage / Buoyancy

• Seismic Loadings

• Stability of Adjacent Ground

• Settlement

• Load Bearing Capacity

• Pavement Design

• Bedding Material

• Compaction

• Handling

• Block Dimensions

• Block Layout and Placement

• Specifications

• Testing and Sampling

• Inspection

PROJECTS

CLIENTS

CONTACT

Inquiries

For any inquiries & questions, please call

99302 54830 or fill out the following form.

Head Office

Shree Insupac

(ISO 9001:2008 Certified)

W/227-228, MIDC Taloja, Taluka Panvel,

District Raigad,Mumbai – 410208, Maharashtra, India

Call us at : 022 2741 2764 (Mob. 99302 54830)